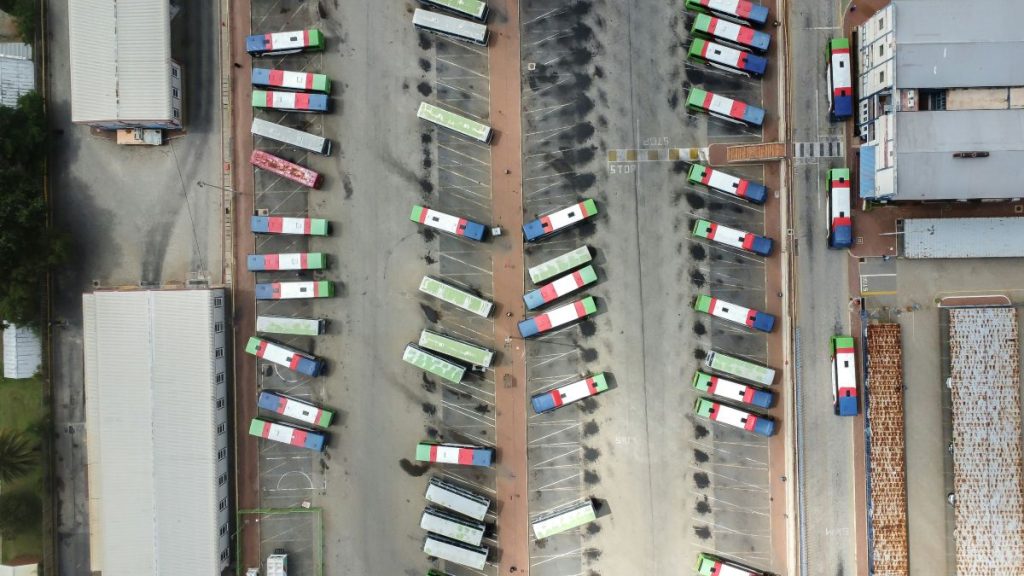

Long viewed as a low-tech bottleneck, the yard is emerging as a critical node in real-time logistics. Here’s how forward-thinking leaders are turning it into a source of speed, control, and ROI.

The Yard’s Strategic Potential Has Arrived

For years, the warehouse yard has sat on the margins of logistics strategy. It was the space between systems—the blind spot between the WMS and TMS, where visibility dropped and inefficiencies stacked up. But that’s no longer acceptable for supply chain leaders trying to maximize throughput, reduce detention, and extract more value from every square foot of infrastructure.

Now, the yard is becoming one of the most strategically important—and data-rich—zones in the network. With the rise of connected technologies like machine vision, autonomous electric trucks, and AI-driven yard management systems (YMS), operators can finally convert the yard into a dynamic control point.

What was once a waiting room is becoming a decision engine.

From Static Space to System Intelligence

Leading firms are moving quickly. Ryder, for instance, is installing machine vision sensors at gates and integrating tablet-based data capture throughout its facilities. The impact isn’t just operational—it’s architectural. Trailer identity, location, arrival sequencing, and digital bills of lading can now be captured automatically. Instead of manual check-ins or static trailer logs, the system flows live data directly into the WMS and TMS.

This enables new forms of orchestration: telling drivers where to park based on inventory readiness, triggering autonomous yard movements, and aligning inbound flow with dock availability. Labor is redeployed. Mispulls vanish. Turnaround times shrink. Crucially, these gains are measurable and repeatable.

Companies like Chamberlain Group, Loadsmart, and Outrider are taking this further, combining AI and computer vision with autonomous vehicles that navigate yards, make decisions on the fly, and update systems in real time. They’re not just digitizing the yard—they’re closing the visibility loop.

For senior directors in logistics, this isn’t about incremental tech—it’s about eliminating your network’s weakest link.

Rethinking Labor, Uptime, and Network Fluidity

The transformation is also shifting how yard labor is managed. What used to require morning walkarounds and radio check-ins can now be handled through automated asset tracking, mobile apps, and systems that self-correct. It frees human teams to focus on higher-value activity—and it reduces the chaos that so often defines live operations.

It also changes the calculus on equipment. Electric yard trucks from firms like Orange EV are now operating under multi-year uptime guarantees, minimizing unscheduled downtime. Meanwhile, Fernride’s fully autonomous terminal tractors are unlocking 24/7 performance at port and distribution yards—cutting out labor availability as a constraint entirely.

What emerges is a smarter, more self-regulating yard—one that reduces friction, boosts trailer velocity, and aligns upstream and downstream systems more tightly than ever before.

A Quiet Revolution in Operational Command

The yard is no longer just a problem to be solved—it’s a signpost for where logistics strategy is headed. As organizations digitize physical assets and inject intelligence into their most overlooked zones, they begin to shift from managing logistics as a chain of events to orchestrating it as a continuous, responsive system. This is less about efficiency gains at the margins and more about a change in posture: from reactive to anticipatory, from fragmented to integrated. The emergence of the smart yard tells us that operational control in the future won’t be built on size or speed alone—but on the ability to sense, decide, and act in real time, at every node.