Addressing the Growing Challenge of Returns

The surge in product returns continues to test the limits of warehouses and supply chains. With inventory pressures and labor shortages persisting, reverse logistics has become a critical focal point for supply chain leaders. Getting returned inventory back into saleable condition quickly is no longer just a goal—it’s an operational necessity.

Returned inventory represents a significant opportunity in today’s constrained supply chain environment. Quickly turning these items into sellable stock helps alleviate inventory challenges and maintain profitability, underscoring the need for speed and efficiency in processing returns.

Strategic Approaches to Reverse Logistics

Reverse logistics has grown far beyond its origins as a back-end challenge. Today, organizations are adopting more holistic strategies, viewing returns as a part of the broader customer journey. The process starts when the customer initiates a return and concludes when the item is either resold or disposed of.

Retail workers are being tasked with an expanded role in the returns process. Instead of simply sending all items back to the warehouse in bulk, many retail teams are presorting returned items to determine if they can be restocked immediately or require further processing. This shift enables warehouses to process returns faster and more effectively, reducing strain on warehouse operations.

Technology Drives Efficiency

Technology is playing an increasingly important role in transforming reverse logistics. Mobile devices, returns management software (RMS), and automated communication tools are helping streamline the process. For instance, RMS platforms can enforce return policies, generate return labels, and provide real-time status updates to customers.

Handheld devices and wearables also simplify the in-store returns process by giving retail associates instant access to data. This speeds up decision-making, reduces errors, and allows teams to prioritize tasks more effectively. Nearly 75% of retailers in Zebra Technologies’ “17th Annual Global Shopper Study” reported plans to invest in such tools in 2025, further cementing technology’s role in enhancing returns management.

The Role of Robotics in the Warehouse

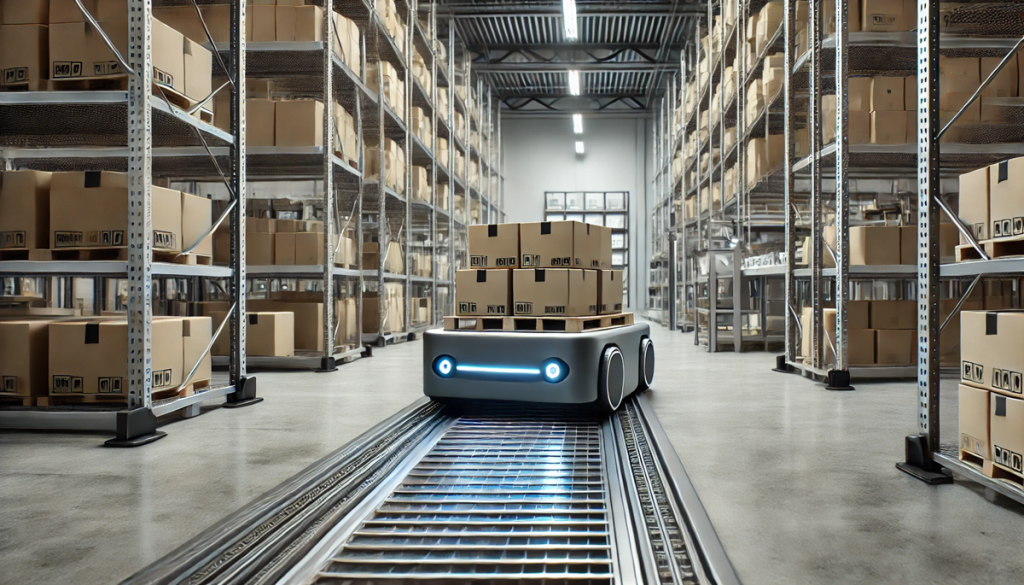

In the warehouse, robotics is emerging as a scalable solution for handling the complexity of reverse logistics. Partnerships like Optoro and Locus Robotics illustrate how autonomous mobile robots (AMRs) can enhance efficiency by automating key parts of the returns process.

Returned items are scanned and placed on robots, which navigate the warehouse to deliver them for restocking or disposal. This reverse-picking approach reduces the physical burden on workers while speeding up operations. The ability to scale robotics solutions during high-return periods and reduce them when volumes decline offers a flexible advantage for warehouse managers.

Scaling Reverse Logistics for Future Success

Scalability is becoming a defining factor in reverse logistics innovation. Warehouses and retailers need solutions that can adapt to fluctuating return volumes without overburdening existing systems. Mobile devices, robotics, and advanced software offer scalable options that allow businesses to ramp up during peak periods and pull back as demand eases.

Furthermore, better integration between retail and warehouse teams can streamline the returns process even further. Encouraging smarter decision-making at the point of return—whether in-store or online—prevents unnecessary delays and reduces operational bottlenecks.

A New Era for Reverse Logistics

Reverse logistics is no longer a behind-the-scenes function—it’s a strategic priority for businesses navigating high return rates and rising customer expectations. By embracing technology, fostering collaboration between retail and warehouse teams, and investing in scalable solutions, organizations can turn returns management into a competitive advantage.

With e-commerce and consumer demands showing no signs of slowing, the ability to efficiently handle returns will remain a cornerstone of supply chain resilience and growth in 2025 and beyond.