Automation in warehouses is heralded as a solution to the dual challenges of increasing demand and labor shortages. However, the transition to automation, such as robotics, demands significant upfront investment and a strategic approach to truly enhance operational efficiency. Mor Peretz, CEO of CaPow, emphasizes that modern warehouses must adapt to diverse needs, from handling bulk shipments to processing individual e-commerce orders.

Labor Challenges and Skill Shifts

The labor shortage is acute, particularly in the Midwest and southern states, where staffing has not rebounded to pre-pandemic levels. Workers are gravitating towards less physically demanding roles, leaving a gap that automation could fill. Yet, this shift necessitates a workforce with advanced skills to manage and interact with new technologies.

Efficiency Expectations vs. Reality

Despite the promise of automation, some warehouses are not meeting performance goals. Peretz identifies issues such as operational misalignment and frequent downtime for maintenance and charging as culprits. The initial excitement for automation can wane as managers confront the practicalities of integrating these systems into daily operations.

Cost Concerns and Energy Overheads

While automation is intended to save costs over time, the initial financial barrier can be significant. As robotic technology becomes a standard operational element, its cost implications, including the energy required for larger robotic fleets, must be factored into budgeting.

Maximizing Robot Output

Robots offer the advantage of potentially continuous operation, increasing output significantly. However, to avoid downtime, innovative charging solutions that power robots without interrupting their workflow are essential. This approach helps maintain a constant operational pace, crucial for facilities aiming to run 24/7.

Towards a “Lights-Out” Future

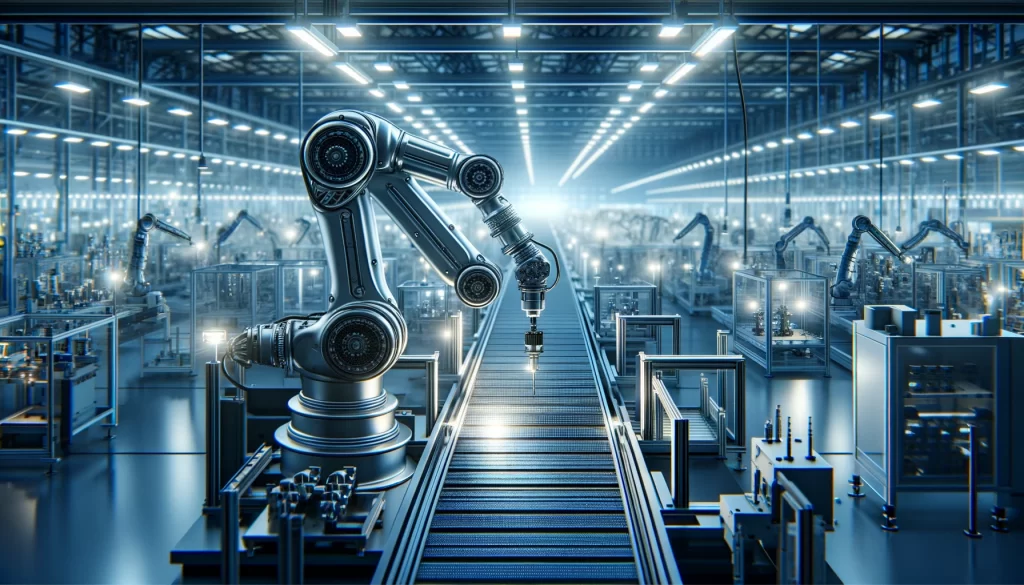

The ultimate goal for some may be a fully automated, human-free “lights-out” warehouse. Such environments are particularly suited to areas hazardous for humans or where product handling is uniform. While complete automation isn’t the immediate goal for most, integrating robots for repetitive tasks while humans handle complex activities is a balanced approach to enhancing productivity.

The key to leveraging the full potential of warehouse automation lies in recognizing the capabilities of robots and optimizing their use to complement human labor, thereby maximizing the return on a significant technological investment.