Amid rising operational costs, trucking companies are turning to digital twin technology to optimize fleet performance, reduce inefficiencies, and improve driver satisfaction in a challenging market.

As trucking companies grapple with rising costs and declining profit margins, digital twin technology is emerging as a transformative tool to address operational inefficiencies and improve asset utilization. By simulating real-world systems in virtual models, digital twins offer trucking companies new opportunities to optimize fleet management and enhance decision-making in real-time.

Rising Costs Demand Innovation

In 2024, operational costs are the foremost challenge for trucking firms, surpassing even driver shortages. According to the American Transportation Research Institute, trucking costs per mile have climbed significantly, reaching $2.27 in 2023. These rising expenses, compounded by lower demand and plummeting rates, forced around 88,000 trucking companies to shut down last year, including major players like Yellow Corp. and Convoy.

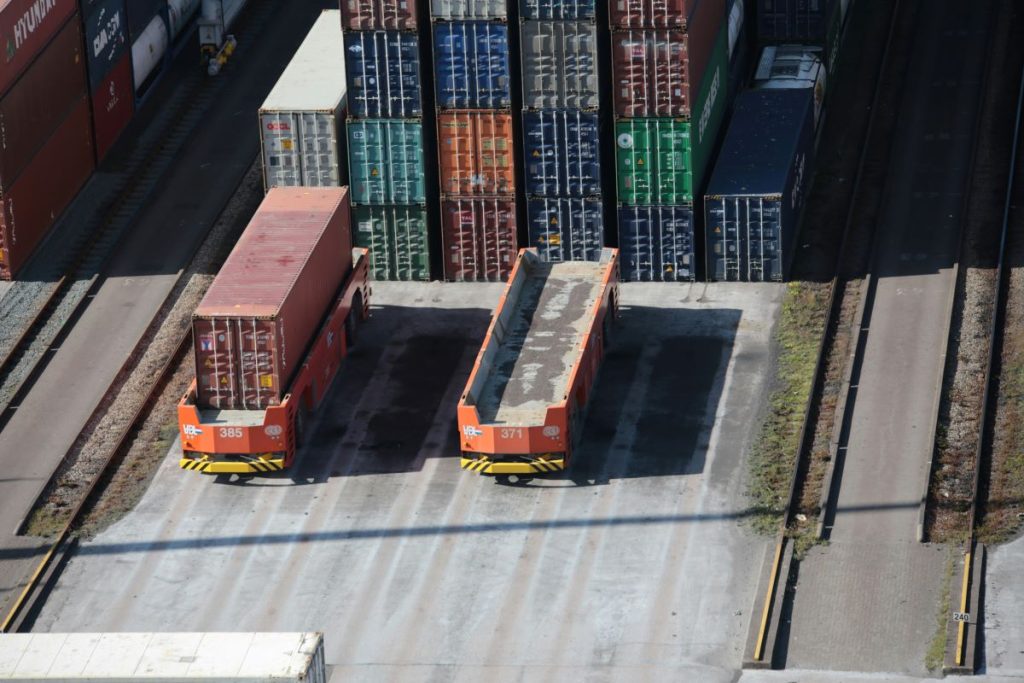

To remain financially viable, trucking companies need innovative strategies to maximize resource utilization. Enter digital twins—a technology rapidly gaining traction across industries due to advances in IoT, AI, and cloud computing. By creating a digital replica of their networks, trucking firms can leverage this technology for detailed fleet analysis and decision-making, potentially reducing costly deadheads and optimizing driver productivity.

Automating Fleet Management and Reducing Deadheads

Manual dispatch methods are becoming obsolete in the face of modern logistics demands. Digital twins provide a real-time model of the trucking network, integrating data on truck locations, driver hours, and planned loads. This dynamic simulation enables planners to evaluate different scenarios, helping identify the most efficient load assignments while adjusting for variables like traffic or weather delays.

For example, digital twins allow trucking companies to combat deadhead miles—those driven without cargo—by identifying the best matching loads for each route segment. This not only boosts revenue per mile but also improves driver pay and satisfaction, as drivers receive more earnings from productive miles. On average, companies see a 20% increase in productive miles per truck when utilizing this technology.

A Path to Sustainable Operations

In addition to operational efficiencies, digital twins offer environmental benefits by reducing unnecessary miles and idle times. Trucking companies adopting this technology align with shippers seeking eco-friendly solutions that meet ESG targets, making them more competitive in today’s market. Additionally, digital twins provide transparency and analytical insights, empowering companies to identify inefficiencies and implement data-driven changes that drive long-term improvements.

As digital twin adoption grows, companies must focus on robust data management and change management within dispatch operations to realize its full benefits. While technology lays the foundation, the transformation will require industry players to embrace change and adopt new operational practices. By investing in digital twins and other innovations, trucking firms can position themselves to weather future market volatility, maintain customer satisfaction, and thrive in a competitive landscape.