Manufacturers are increasingly recognizing the role of Artificial Intelligence (AI) in optimizing supply chain management. Despite supply chain being a top production challenge and a notable AI use case, it is often overlooked when deploying AI. This could be due to the belief that AI alone cannot solve supply chain issues. However, manufacturers are now focusing on what they can control – the factory floor. By focusing on machine health, process health, and innovative integrations, manufacturers can increase reliability and predictability, leading to a positive impact on the supply chain.

The Power of Machine Health and Process Health

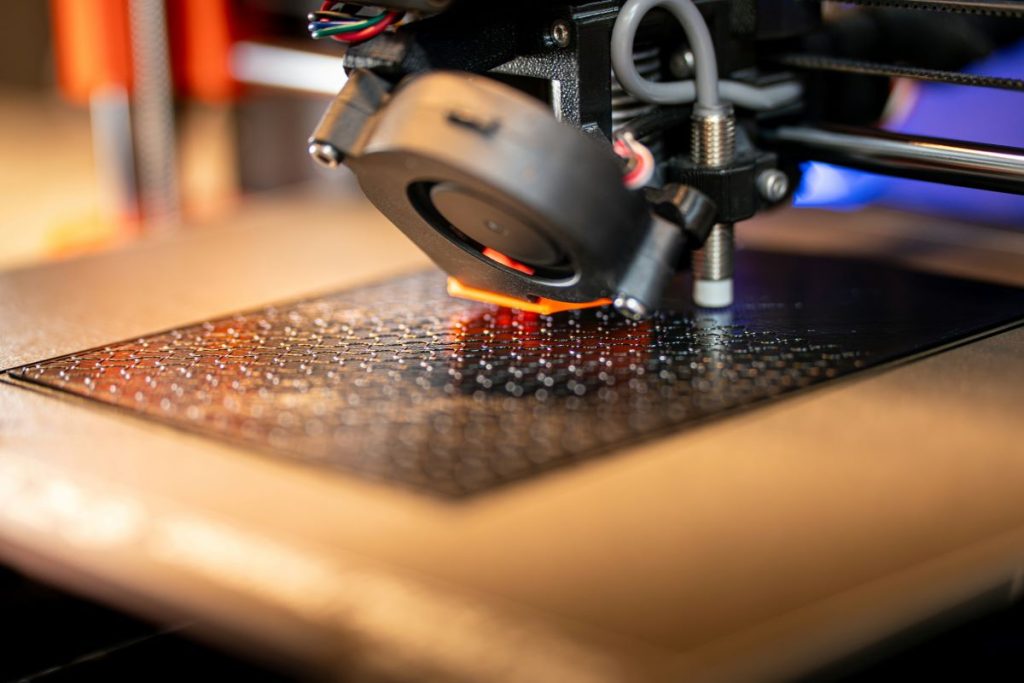

Continuous monitoring of assets, driven by AI-powered insights, ensures that machines are running properly and unnecessary downtime is eliminated. AI-driven, real-time machine health alerts can catch issues before they occur, including those that might be missed by humans. Similarly, AI-powered process health systems can provide manufacturers with real solutions for fixing inefficiencies, preventing production loss, and realizing greater productivity from machines and processes.

The Breakthrough of Parts-as-a-Service (PaaS)

AI-driven PaaS applications are proving to be a game-changer for manufacturers looking to improve supply chain management. By integrating PaaS with machine health, manufacturers can proactively and cost-effectively replace machine parts, minimizing delays and optimizing spare parts management.

In enhancing the supply chain, manufacturers must start on the factory floor. Consistently improving operations by focusing on machine health, process health, and spare parts management is crucial. Working with a trusted partner that understands key objectives and has the necessary technology can be a good starting point.